Case: Apollo Oil Phase II

CHALLENGE: AUTOMATE INTERNAL LOGISTICS

Apollo Oil would like to improve its logistic operation within its premises. When the truck arrives, Apollo would like to automate the arrival, weighting and departure processes. Besides, the company aims to increase the truck visibility by having truck information in real time manner.

SOLUTION

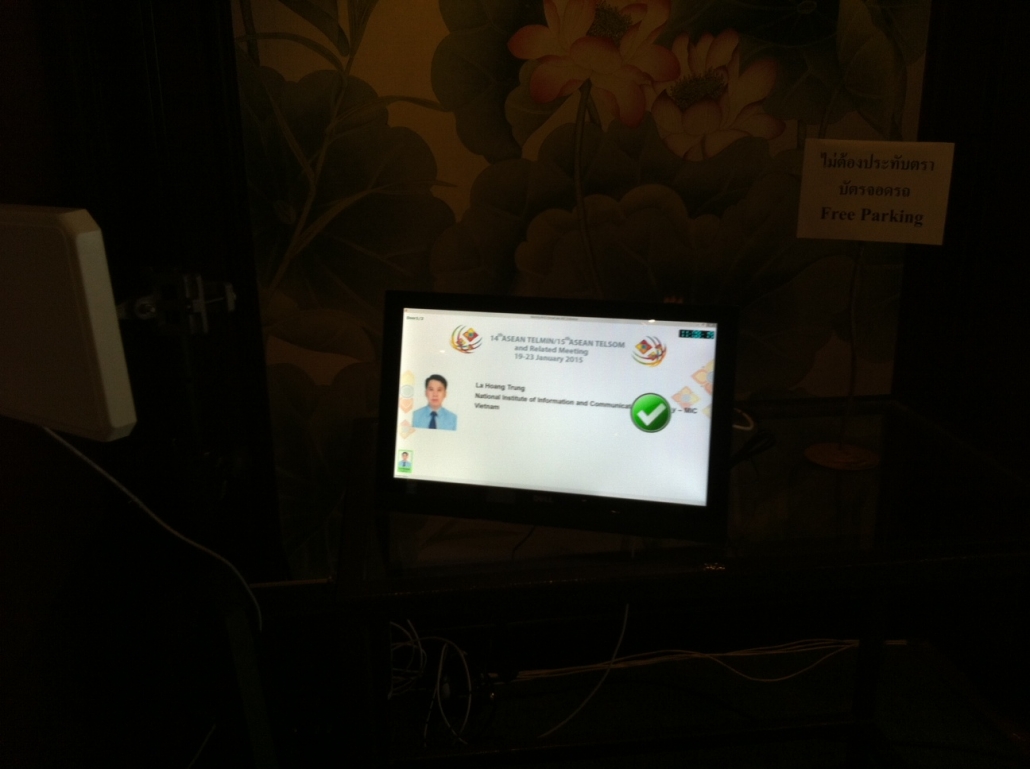

Passive RFID technology is selected to be used to meet the objectives. Each truck is tagged with a outdoor RFID label. The tags are read automatically with the reader located at the entrance when the trucks arrive the factory. After reading by the reader, the truck information is forward to data base application. The staff at the warehouse will be able to prepare loading operation in advance. After the loading, the truck will be moved to weighbridge. Its information will be displayed on the weight program automatically. When the staff confirmed its weights, all truck information is kept in the data base preparing for exit the site. With this solution, Apollo can eliminate the human operation on the internal logistic.

RESULTS

- Give better fleet visibility for the logistics within its site

- Eliminate human data entry

- Truck status is digitalized in measurable format, while makes it possible to monitor and improve operation.